Range TNOSCT

Technical parameters

Output range:

Rated voltage:

Tapping on primary:

Secondary voltage:

Frequency:

Vector group:

Cooling:

Winding conductor material:

Isolation class:

Protection degree transformer:

Max. average temperature rise:

|

10 ÷ 2500 kVA

up to 35 kV

±2x2,5 % (or other)

400 V (or other)

50 Hz

Dyn1

ONAN

Cu nebo Al

A

IP54/IP00

65/60 K

Parameters and drawings |

|

Main features

TNOSCT transformers are almost maintenance-free, hermetically sealed and completely filled with oil. They are designed to operate in both normal and extreme climatic conditions in indoor and outdoor environments. On request and according to the technical requirements of a version are made with a conservator. The tanks are fitted with double anti-corrosion coating RAL 7033. Transformers are usually filled with mineral oil Nytro Taurus (without PBC substances). At the customer's request can be used environmentally degradable synthetic oil MIDEL or vegetable oil BIOTEMP. These types of oils reduce environmental threats in case of undesirable leakage of oil from the transformer.

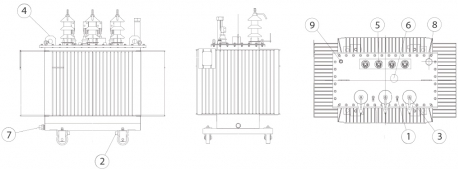

Standard accessories

1.-2. grounding terminals M12x25

3. MV bushings – DT20NF60

4. lifting lugs

5. LV bushings – 1kV/3150 EN 50389 |

6. Off load tap changer

7. safety valve

8. oil filling pipe

9. thermometer pocket |

Accessories on request

- Twin-contact dial thermometer

- Oil level indicator

- Overpressure valve with or without auxiliary contacts

- Plug-in connections MV side

- Auxiliary service box, protected model (IP44 or IP55)

- On load tap changer

- Anti-vibration supports

- Integrated safety system R.I.S.

- Electrostatic screen between primary and secondary

- Spark gap rods

- galvanized tank

other accessories to be agreed upon with customer

Testing

Each transformer is tested at our test room with routine tests in compliance with IEC60076, that is:

- measurement of winding resistance

- measurement of the transforming ratio and control of the connection group

- measurement of losses and short circuit voltage

- measurement of no load losses and no load current

- checking of insulation with applied voltage

- checking of insulation with induced voltage

All kinds of type tests and special tests indicated by regulations can be carried out at the customer’s request:

- heat run test with simulated load method

- impulse withstand test with full and chopped wave

- measurement of noise level

- measurement of harmonic contents of the no load current

- measurement of homopolar impedance

- measurement of winding capacitance

- dynamic short circuit withstand test (to be carried out by an authorized external lab)

other special tests to be agreed upon with customer from time to time (electromagnetic emissions, thermal shocks…).

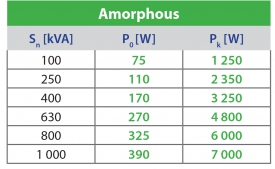

Range AMORPHOUS

In the range of products you can also find oil transformers with amorphous magnetic core. Amorphous materials have significant affect on the transformer losses on empty (P0). Difference loss P0 versus standard distribution transformer makes up 80%. Transformers produced by this technology are environmentally friendly and contribute significantly to reduce energy consumption.

Technical parameters

Output range:

Rated voltage:

Tapping on primary:

Secondary voltage:

Frequency:

Vector group:

Cooling:

Winding conductor material:

Isolation class:

Protection degree transformer:

Max. average temp. rise:

|

10 ÷ 2500 kVA

up to 35 kV

±2x2,5 % (or other)

400 V (or other)

50 Hz

Dyn1

ONAN

Cu or Al

A

IP54/IP00

65/60 K

Parameters and drawings |

|

Production technology

Technology of amorphous sheet is based on the method of rapid cooling of liquid metal which allows to produce strip with a thickness of several tens of microns in order of 0.02 mm, and compared with the best steels for electrotechnology, these strips have only one-third loss. By rapid cooling (about 1-2 ms), which prevents the growth of crystalline grains, arises from the liquid to solid material. To the cooling occurs at a rotating cylinder to which is applied the liquid metal from which it arises amorphous structure with different characteristics in comparison with typical metallic crystalline substances.

Amorphous magnetic materials are characterized by high permeability and low magnetic anisotropy (i.e. in all directions with approximately the same magnetic properties). Products made from these materials have a much lower power dissipation.

For distribution transformers are used amorphous alloy Fe-based and have high values of the saturation induction Bs simultaneously with low losses. These materials have extremely low magnetization losses 0.16 W / kg (at a frequency of 50 Hz and Bmax = 1.45 T). The anisotropic sheet has these specific losses in range from 0.49 to 0.72 W / kg.

Porovnání transformátorů s amorfním jádrem s konvenčními nízkoztrátovými distribučními transformátory

|

|

| Přehled transformátorů s amorfním jádrem od společnosti ABB pro napěťovou hladinu 22 kV |

Přehled konvenčních nízkoztrátových distribučních transformátorů pro napěťovou hladinu 22 kV |

Příklad úspory při nasazení transformátoru s amorfním jádrem v bioplynové stanici

Bioplynová stanice je osazena kogenerační jednotkou o výkonu 550 kW, která je v provozu 8000 hodin za rok. Zbylých 760 hodin v roce je bioplynová stanice mimo provoz.

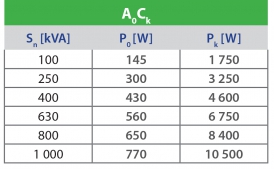

V následujícím přehledu je porovnán konvekční transformátor o výkonu SN = 630 kVA se sníženými ztrátami A0CK (tj. P0 = 560 W, PK = 6750 W) s transformátory s amorfním jádrem o výkonu SN = 630 kVA a 800 kVA, které mají ztráty P0 = 270 (resp. 325) W a PK = 4700 (resp. 6000) W.

Při tomto režimu transformátor se sníženými ztrátami za rok spotřebuje 45 636 kWh elektrické energie, transformátor 630 kVA s amorfním jádrem 31 022 kWh a transformátor 800 kVA s amorfním jádrem pouze 25 288 kWh elektrické energie. Z těchto výsledků zřetelně vyplývá, že konvekční transformátor, ačkoli má snížené ztráty, nemůže konkurovat transformátorům s amorfním jádrem.

Rozdíl ve spotřebě elektrické energie mezi konvekčním transformátorem 630 kVA a transformátorem 800 kVA s amorfním jádrem je 20 348 kWh za rok. Při výkupní ceně 3,55 Kč / kWh, která je platná pro bioplynové stanice v roce 2013 bude roční úspora činit až

72 235 Kč.

| Pro přehlednost uvedených údajů můžete prostudovat graf a tabulku na uvedeném letáku nebo si zapomoci uvedeného vzorce sami ověřit, kolik ušetříte snížením ztrát právě u vámi provozovaného transformátoru. |

|